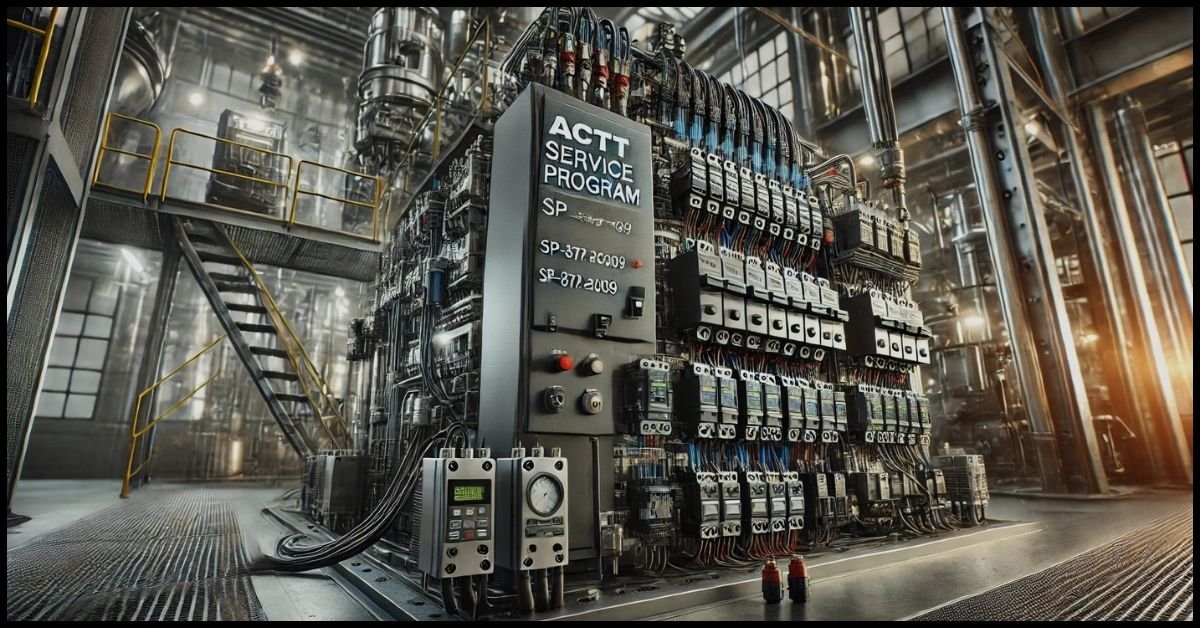

ACTT Service Program SP 3-872-009 Shutdown Harness shutdown harness plays a crucial role in industrial applications, ensuring safety and operational efficiency. Understanding this component can prevent accidents, ensure smooth systems functioning, and maintain equipment longevity. This guide delves into the technicalities, significance, and proper usage of the ACTT shutdown harness.

Understanding the ACTT Service Program SP 3-872-009 Shutdown Harness

The ACTT Service Program SP 3-872-009 Shutdown Harness shutdown harness is an essential safety component in industrial machinery. This harness is designed for specific equipment and ensures controlled shutdowns during emergencies or scheduled maintenance.

Importance of the Shutdown Harness

The shutdown harness is vital in maintaining safety standards. It prevents equipment from running beyond safe limits and helps avert operational hazards by initiating automatic shutdowns when needed. This tool safeguards both personnel and machinery.

Key Features of the Shutdown Harness

- Durability: Built to withstand harsh conditions, the shutdown harness is highly durable.

- Automatic Functionality: It offers seamless automation for shutdowns during malfunctions or specific situations.

- Compatibility: Designed for particular systems, ensuring easy integration into existing machinery.

- Reliability: Highly dependable in critical moments, preventing catastrophic equipment failure.

Installation Process of the Shutdown Harness

Proper installation of the ACTT Service Program SP 3-872-009 shutdown harness ensures it works efficiently and offers the intended safety benefits.

Step-by-Step Installation Guide

- Preparation: Ensure all machinery is turned off and secure before installation. Gather the required tools and manuals for guidance.

- Harness Connection: Connect the harness to the designated points per the manufacturer’s instructions. It’s essential to follow each step precisely to prevent malfunctioning.

- System Configuration: Once connected, configure the system to recognize the harness. This ensures proper communication between the machinery and the harness.

- Testing: After installation, test the system to ensure it triggers automatic shutdowns as needed. Recheck the connections and configurations if the system doesn’t shut down correctly.

Safety Precautions During Installation

- Always follow the safety protocols during installation to avoid electrical hazards.

- Ensure that no live machinery is connected during the process.

- To guarantee worker safety, wear personal protective equipment (PPE).

Benefits of Using the ACTT Service Program Shutdown Harness

The ACTT SP 3-872-009 shutdown harness provides several benefits that enhance operational safety and productivity.

Enhanced Safety Standards

The primary function of the shutdown harness is to ensure safety. It protects the workforce by automatically shutting down machines during hazardous conditions, reducing the risk of injury or accidents.

Cost-Efficiency

Although this harness may represent an initial investment, it saves significant costs in the long run by preventing equipment damage, reducing downtime, and avoiding accidents. Regular shutdowns prevent costly repairs, making it a cost-effective solution.

Longevity of Equipment

Consistent use of the shutdown harness can significantly extend the life of industrial equipment. Automatically controlling shutdowns reduces the strain on machinery, lessening wear and tear.

Troubleshooting Common Issues with the Shutdown Harness

Despite its high reliability, users may occasionally face minor issues with the ACTT shutdown harness. Proper troubleshooting can quickly resolve these problems.

Common Problems and Solutions

- Connection Errors: Sometimes, the harness may not connect properly to the machinery. Recheck the wiring and ensure all points are securely connected.

- Malfunctioning Shutdowns: If the system shuts down prematurely or fails to shut down, ensure the configurations match the system’s operational parameters.

- Wear and Tear: Regularly inspect the harness for any wear or damage. Replace components if they are showing signs of deterioration.

Professional Maintenance Services

If troubleshooting does not resolve the issue, it is advised to seek professional maintenance services to avoid further complications.These experts possess the necessary equipment and expertise to resolve the issue.

FAQs

What is the primary purpose of the ACTT Service Program SP 3-872-009 shutdown harness?

The shutdown harness’s primary purpose is to enhance industrial machinery’s safety by automatically shutting down the system during emergencies or scheduled maintenance.

Can the ACTT shutdown harness be used with all industrial equipment?

No, the ACTT SP 3-872-009 shutdown harness is designed for specific types of equipment. Always check compatibility before installation.

How often should the shutdown harness be tested for functionality?

Testing the shutdown harness during regular maintenance checks, ideally every three to six months is advisable to ensure proper functionality.

What safety measures should be taken during the installation of the shutdown harness?

Ensure all machinery is powered off, and wear protective gear during installation. Follow the manufacturer’s instructions closely to prevent any mishaps.

What should I do if the shutdown harness is not functioning correctly?

First, troubleshoot by checking the connections and configurations. Seek help from a qualified technician if the problem continues.

How does the shutdown harness improve equipment longevity?

The shutdown harness reduces the operational stress on machinery by ensuring controlled shutdowns, which minimizes wear and tear and extends the life of the equipment.

Conclusion

The ACTT Service Program SP 3-872-009 shutdown harness is critical to industrial safety and operational efficiency. Proper installation, regular maintenance, and understanding of its functionality can drastically reduce downtime, protect workers, and increase equipment longevity. Whether you’re responsible for managing industrial systems or are part of a maintenance team, familiarizing yourself with the shutdown harness ensures you’re prepared for any emergency shutdown scenarios.